Project details

- Project Name: Conceptual design and FEED of the GR5 Gas Pipeline

- Country: Algeria

- Project Location Within Country: Gas pipeline in South Western Sahara, crossing the Grand Erg Occidental (Sand Dunes) running from Aoulef (near Reggane) to Hassi R’Mel

- Name of the Client: SONATRACH – TRC (Pipeline Transmission Division)

- Start Date: August 2009

- Completion Date: July 2011

Project description

The GR5 is a new 48″ gas transmission system intended to collect the gas to be produced by 9 fields in the South West of Hassi R’Mel. The pipeline route crosses desertic areas, the Aoulet plain, Tademait Plateau, a vast sand dunes area ‘Grand Erg Occidental’, and then Hamada areas up to Hassi R’Mel.

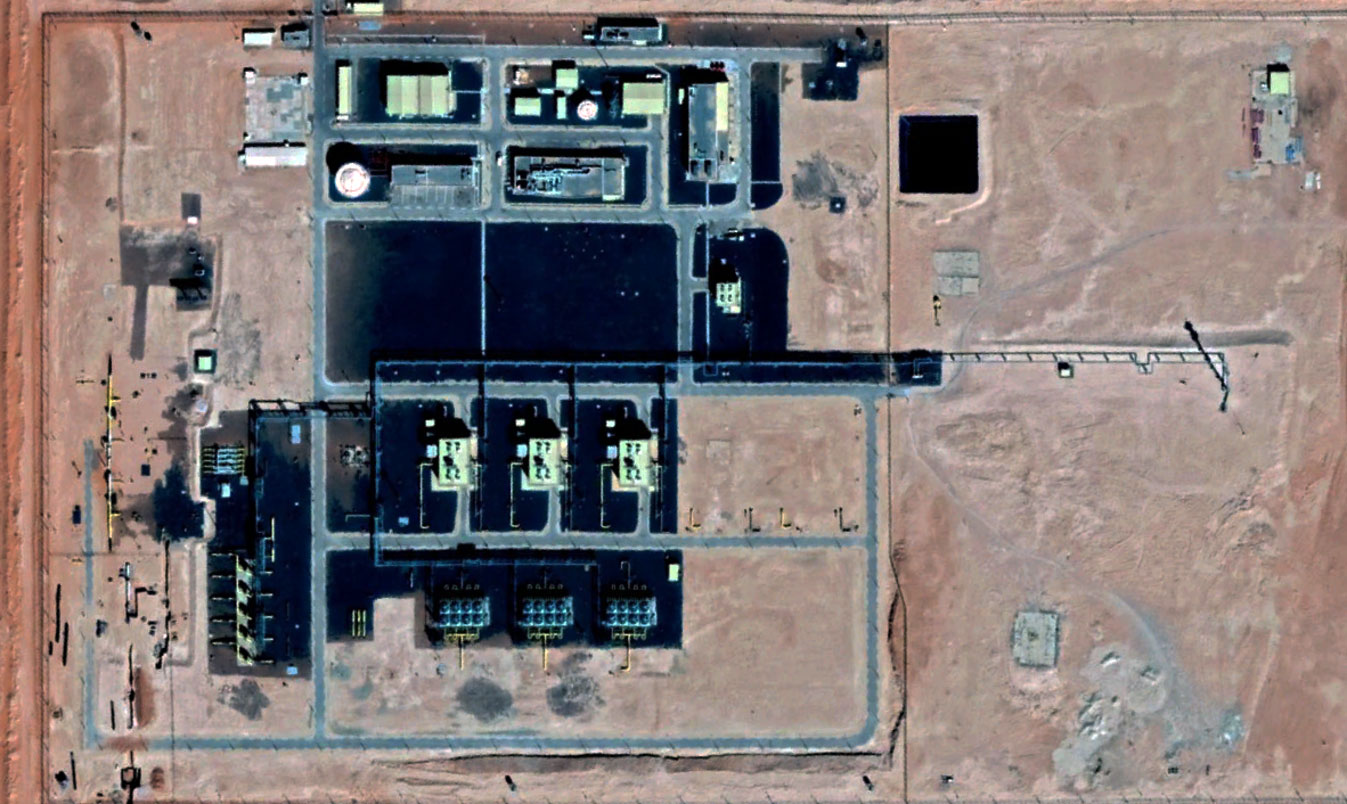

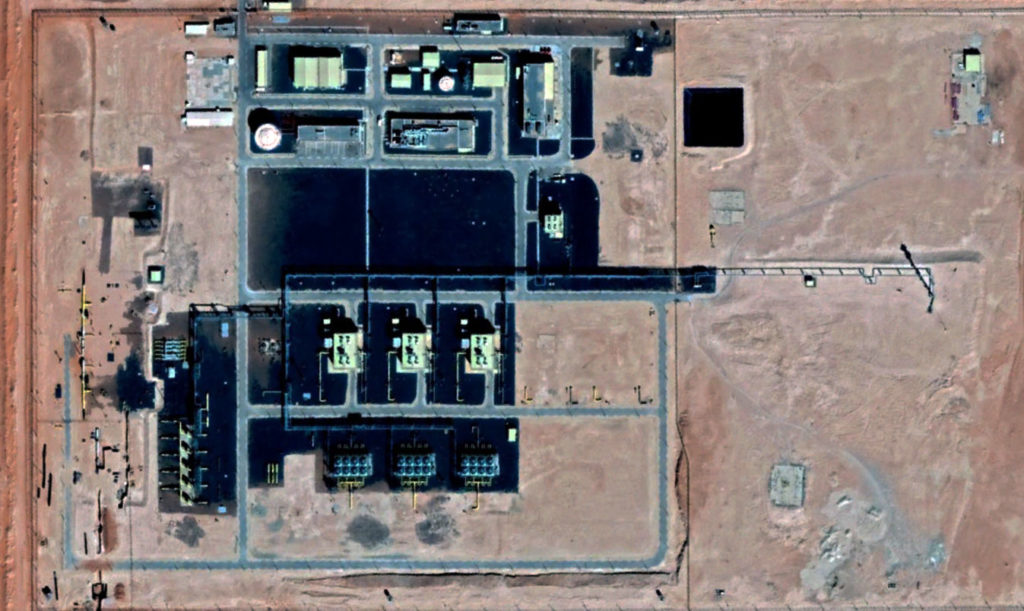

The GR5 transmission system includes a 760 km pipeline 48’’, one intermediary compression station, a final compression station and injection stations at tie-inpoints with branch transporting gas from the field CPFs. A 320 km 48’’ loop will be installed in phase 1 and will be further expanded in the final development phase.

Each compression station is equipped with 3 x 28 MW ISO gas turbine centrifugal compressor sets.

Scope of Work

Pre-FEED:

- Data collection: environmental, climatic, landownership, …

- Route study:

- Identification of a constructible route within a 5-km wide corridor

- Setting up a Geographical Information System (ArcGIS)

- Acquisition and analysis of satellite imagery with different resolutions and bands.

- Geological/geotechnical interpretation, terrain evaluation and sand dune migration study

- Incorporation of Numerical Terrain Model

- Site surveys on some sections of the route: validation of NTM, assessment of geotechnical risks

- Hydraulic study of the GR5 transmission system development phases and techno-economic optimisation

- Constructability study pipeline and stations

- Conceptual design of the transmission system: design philosophies, evaluation of possible compression configuration, recommendations.

FEED (Front End Engineering Design) to provide all technical documents to prepare EPC tender documents

- Detailed route studies:

- Topographical survey by airborne LIDAR and aerial photography

- Preparation of alignment sheets 1/10,000 and special crossing drawings

- Detailed hydraulic study

- Engineering design of pipeline and stations (2 compression stations, 6 injection stations (with metering)

- Environmental Impact Study

- Risks and danger study for pipeline and stations. HAZID – HAZOP review

- Geotechnical surveys: seismic refraction, resistivity measurements, penetrometer tests and borings

- Budget cost estimate

- Preliminary implementation schedule

- Preparation of the documents for the application for construction permit.

All Projects: